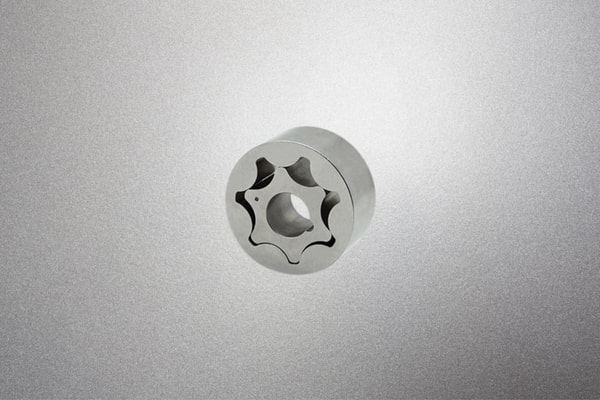

Powder Metallurgy Pump Rotor & Stator

H&Z has been providing high-standard pump rotors & stators to more than 40 countries and regions around the world. We have a very strict powder metallurgy engineering system, able to provide you with a professional powder metallurgy pump rotor & stator.

Our precise forming capabilities and manufacturing processes allow us to maintain tight tolerances for demanding applications. Please contact us for more information on how H&Z can help you.

Pump Rotor & Stator Product Display

Benefits of Powdered Metal Pump Rotor & Stator

Additional benefits to using PM for structural components include the following:

- Lower tool cost

- Consistent reproductivity

- Tight tolerances as compared to castings and stampings

- Cost effective as a manufacturing process

- Ability to accommodate low to high volume (5000 to 5M+ annual volume)

In addition, the design features of powdered metallurgy eliminate the need for draft angles and sheer which would be necessary in a casting or stamping design.

Contact Us to Customize High-precision Pump Rotor & Stator for Your Project

H&Z is a leading manufacturer of powder metallurgy Pump Rotor & Stator, and our modern factory is equipped with a variety of state-of-the-art automation and material handling systems, further increasing the efficiency of an already efficient process. We also offer extensive pump rotor finishing capabilities; including services such as machining, plating and heat treatment.

Why everyone chooses H&Z

- We use our engineering capabilities, strong development capabilities, and structured process design to meet the individual needs of our customers.

- Our powder metallurgy products go through a strict approval process and are regularly inspected at different intervals. The process guarantees zero error tolerance in development and series production

- We have professional factories in China, and our quotations are competitive, saving you more costs and fees.