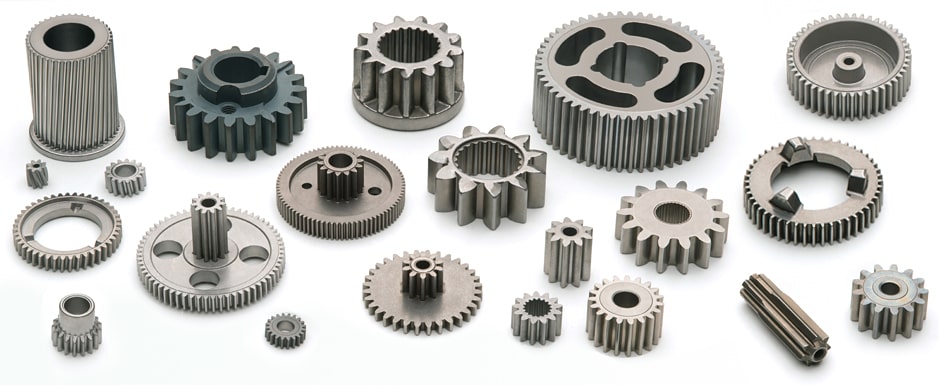

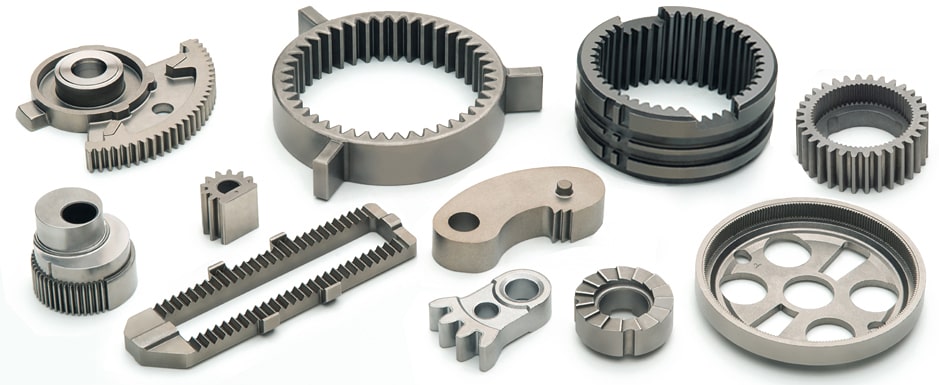

Powder Metallurgy Gear & Rotating Parts

As a leading powder parts manufacturer and supplier in China, H&Z provides various types of powder metallurgy gears and rotating parts to customers in various countries around the world.

Gears manufactured through the powder metallurgy process offer a cost-effective alternative to traditional machined steel or cast iron gears. The powder metallurgy (P/M) process produces net or near-net-shape parts, resulting in finished parts that in many cases require little or no machining. Thus, the process provides dimensional tolerances and mechanical properties compatible with many applications.

Benefits of Using Powder Metallurgy to Make Gears

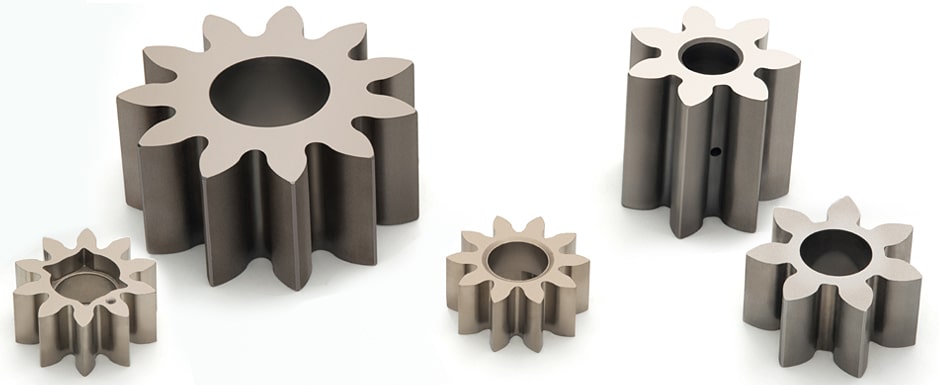

The primary reason that powdered metal gears may be preferred over more traditional gear materials is cost. In large production quantities, it is less expensive to manufacture a gear made of powdered metal than a gear made of iron or steel. First, less energy is used during manufacture, and there is also very little material waste. The manufacturing cost is also generally less when considering that many powdered metal parts do not require very much if any, machine finishing.

Other features that make powdered metal appealing have to do with its material structure. Due to the porous composition of powdered metal gears, they are lightweight and typically run quietly. Also, the powder material can be uniquely mixed, producing unique characteristics. For gears, this includes the opportunity to impregnate the porous material with an oil, resulting in gears that are self-lubricated.

Contact Us for Custom High Precision Gear for Your Project

H&Z is a leading manufacturer of powder metal gears and rotating parts, our modern factory is equipped with various state-of-the-art automation and material handling systems, adding further efficiency to an already efficient process. We also offer extensive gear finishing capabilities; these include services such as machining, plating, and heat treatment.

Why everyone chooses H&Z

- We use our engineering capabilities, strong development capabilities, and structured process design to meet the individual needs of our customers.

- Our powder metallurgy gears go through a strict approval process and are inspected regularly at various intervals. This process guarantees zero error tolerance in development and series production

- We have professional factories in China, and our quotations are based on competitive, saving you more costs and expenses.